The global phenolic resins market size was valued at USD 11,220.9 million in 2021 and is expected to expand at a CAGR of 6.2% over the forecast period, 2025 to 2034. Growth of multi-functional furniture fixed with acceptance of online retailing methods in order to reduce the operating expenditures involved in sales and distribution are anticipated to poise development in the industry till 2034.

Phenolic resin, a class of thermosetting resins, is a synthetic polymer which is produced by the reaction of phenol or by substituting phenol with formaldehyde. Phenolic resins have wide range of applications including molding, wood adhesives, insulation, and so on which makes it suitable for several end-use industries. Automotive industry can broadly classified as companies that manufacturers the cars and companies that manufacture car parts. Companies. This Industry uses phenolic resins as they are used to manufacture car’s dashboards, flooring, engine components door panels and many more other products.

The retrieval of the automotive market in the U.S. and the upsurge in the sales of passenger cars have increased the consumption of novolac resins. The industrialists completely rely on composites that are lighter in weight and bonding agents to witness the strict emission guidelines. Novolac resins are extensively used in abrasives, adhesives, carbon binders, and insulation, which is boosting its demand in the end-use industries.

Domestic manufacturing of wall panels, cabinets, and furniture is beholding growth due to the rise in residential housing that utilizes engineered wood products. The economic recovery in the U.S. is expected to put forth lucrative opportunities for these laminates. Moreover, phenolic resins are extensively used to produce industrial and decorative laminates for the construction industry.

The primary reasons which is strengthening the demand for the phenolic resin’s market is the use of phenolic resins across several automotive parts. They are used as binders for friction materials, brake linings, clutch plates and brake pads. These resins are used as friction materials provide superior adhesive performance .Some of the important components such as transmission parts, fuel pumps also use phenolic resins as they provide excellent durability and good thermal insulation. Also, these phenolic resin is also easy to mold into a variety of shapes and complex contours. These qualities make them adaptable to several environments. Besides this phenolic resins are used in car interiors, decorative laminates, rubber tyres and lightweight polyurethane foams for vehicle door insulation. Apart from its usage in the automotive sector the demand for the passenger vehicle has again started to pick pace in APAC and North America region which in turn will help the market to grow.

The demand for phenolic resins has been severely affected by the outbreak of COVID-19 and the subsequent halting of various industries across the globe. The building & construction and automotive industries were affected in major countries due to supply shortages, lockdowns, and production suspensions in the early months of 2020. The demand for new vehicles in pandemic-affected countries was low due to lockdowns and restrictions to curb the spread of the virus.

The use of resins have completely changed the aerospace industry through its low weight molding techniques. It has considerably reduced the weight of the aircraft’s by replacing the metal. Besides this, phenolic resins are also being used in critical surface paths through decorative laminate materials which increases the customer experience. Phenolic resins are used in Laboratory furniture and work surfaces which are suitable for chemical, biological, and clinical testing labs. Labs require surfaces that must have resistance against bacteria and chemical. Phenolic resins are thus used to provide containment-free surfaces. Phenolic resins are excellent non-conductors and most reliable used as insulator. They are used in electrical castings as it has high toughness and excellent mechanical & electrical insulating properties. They are also used for laminating on board applications. Resoles are used for low-end applications such as radio, toys and calculators.

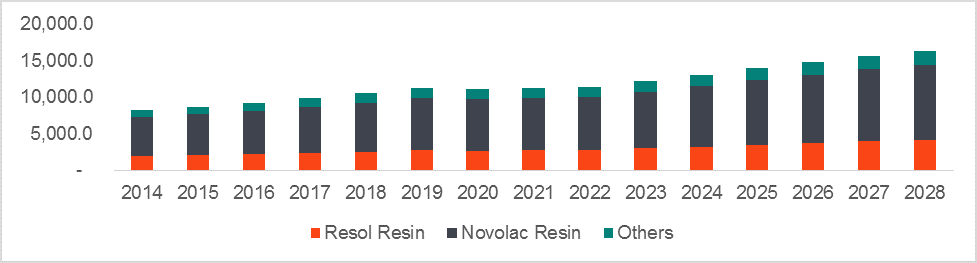

The market is divided into novolac and resole. Resoles have been further classified into solid and liquid resins. Novolac resins led the phenolic resins market and are expected to witness heavy demand owing to superior properties of the product such as solvent resistance, hardness, and heat. The escalation in the electrical and electronic industry in the countries in North America is also driving growth.

Novolac resins are produced from reaction of phenol and formaldehyde in presence of acidic catalyst. Some of the significant characteristics associated with novolac resins include lightweight, high thermal stability, and high strength which is anticipated to drive the segment growth. Moreover, these resins can be molded easily which makes it suitable of a number of applications. These resins are able to exhibit almost 15% higher bursting strength and high air permeability.

Furthermore, resole resins are anticipated to emerge as the fastest-growing product with a CAGR of around 5.8% over the forecast period. The developing economies such as the Asia Pacific are spending massively on construction, which is expected to drive the growth of the market during the forecast timeframe.

Globally, APAC region has the highest market share owing to presence of phenolic resins manufacturers across this region. Also, this region has the highest population and growing economy which largely boosts the Automotive, Building & Construction, and Furniture markets at large thereby directly benefiting the phenolic resin market. Besides this, the environmental laws are not stringent in developing economies like India and some South East Asian countries which makes them global suppliers for these products.

Some of the prominent companies manufacturing phenolic resins products include Ashland Global holdings Inc, BASF SE, DIC Corporation, Showa Denko K.K, Sumitomo Bakelite Co Ltd, Allnex Group, Prefere Resins Holding GmbH, Chemovate Ltd, Dyna Chem Inc, Fenolit D.D., Georgia- Pacific Chemicals LLC and several among others. Most of the companies are giant companies having diversified portfolio and have their presence across different parts of the world. The giant companies usually adopt merger and acquisition strategies as there was recent decline in the chemical industry due to impact of coronavirus across several businesses and stringent environmental regulations across developed countries. Hence, the giant companies found this as great opportunity to acquire smaller companies that either provided differentiated products or has completely new chemical business.

To ensure high-level data integrity, accurate analysis, and impeccable forecasts

For complete satisfaction

On-demand customization of scope of the report to exactly meet your needs

Targeted market view to provide pertinent information and save time of readers

A faster and efficient way to cater to the needs with continuous iteration

Focus on Data Accuracy & Reliability

75+ Clients in Fortune 500

All your transactions are secured end-to-end, ensuring a satisfactory purchase

Ensure the best and affordable pricing